Once your design is complete easily order o-rings online from the worlds largest o-ring inventory network. Commonly called a crush seal design triangular groove designs have established a proven track record of success in numerous industries.

Groove Design O Ring Seals Minnesota Rubber Plastics

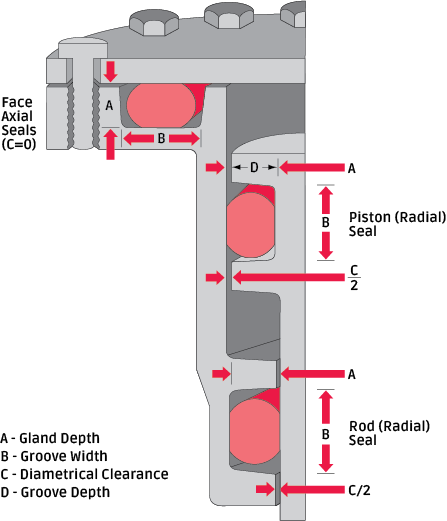

The o-ring gland design is very simple for face seals.

. In a triangular groove the O-ring is pressed equally against three mating surfaces. This o ring crush seal design from Yiho Polytek enjoys the advantages of high ozone and chemical resistance good flexibility and elasticity excellent oil resistance etc. O-rings are primarily used to prevent the loss of a fluid or gas.

Groove Flange Oring Cross Section L Groove Depth Squeeze G Groove W Liquid 0005 G Groove W Vacuum 0005 R Groove Radius Metric Oring Groove Design. Please contact the local ERIKS repre-sentative if an application does not clearly fall into these design parameters. Crush installation is when an O-ring is crushed into a space having a cross-section different from that of a standard gland.

Down to 008 ID. Squeezed at an angle to the O-rings axis crush seals are used in such simple applications as the one depicted in Illustration 44. Design guidelines for O-Rings.

O-Ring Installation Design and Specification Static Flange Application. This o ring crush seal design from Yiho Polytek enjoys the advantages of high ozone and chemical resistance good flexibility and elasticity excellent oil resistance etc. Traditionally an effective seal is created when a rubber seal element is pressed tightly between two mating components.

HITECHSEALSCOM 3 Compound Specification Guide Prefix Material Duro. Dual turn rings conform to MS 28782 and match the dash numbers of an AN 6227 series of O-rings. Free easy returns on millions of items.

Commonly called a crush seal design triangular groove designs have established a proven track record of success in numerous industries. A stretch greater than 5 on the O-ring ID. Providing you with timely online service and quick delivery we warmly welcome you to buy our products.

Now follow the steps below to design your own o-ring seal and o-ring groove. The O-Ring is confi ned in a triangular recess made by machining a 45 degree angle on the male cover. We have been specialized in manufacturing quality rubber products since 1994.

Over 2000 sizes of MicrOringTM seals from 039 ID. 5pcs 13mmx18mmx15mm Copper Flat Ring Sealing Crush Washer from wwwwalmartca. The O-ring is crushed into a space having a cross-section different from that of a standard gland for example triangularWhile it is an effective seal the O-ring is permanently.

Face Seal Groove Design Flange Dimensions apply to all laterally loaded orings in static face seal grooves for both liquid pressure and vacuum applications. Step 2 Make sure that the material you choose will withstand the temperature of your system by going to this rubber temperature range chart. Is not recommended because it can lead to a loss of seal compression.

Most O-ring seals can be classified into one of the three. Simply cut out a circular groove into one of the plates and leave the other plate completely flat the groove will have a squaretrapezoidal cross section and the dimensions are conveniently already calculated and laid out in tables in the Parker O-ring Handbook. However O-rings can be used as dust seals drive belts or on rotating shafts.

For more than 40 years Marco Rubber and Plastics has been offering custom and standard o-rings and other sealing solutions for multiple industries. The only time you. Traditionally an effective seal is created when a rubber seal element is pressed tightly between two mating compo- nents.

In a triangular groove the O-ring is pressed equally against three mating surfaces. Static Applications There are five types of static O-ring applications. The same sealing principle applies to crush type seals used in recesses of straight thread tubing bosses.

A radius of005 on the groove corners is advisable. O-ring Gland Design The following pages contain basic O-ring gland design information. O Ring Crush Seal Design.

Step 1 Choose your rubber properties by going to our O-ring Material Guide section. Learn More Reciprocating Seals In a reciprocating seal there is relative reciprocating motion between the inner and outer elements. O-Ring Leak Rate Equation and Calculator.

Squeezed at an angle to the O-rings axis crush seals are used in such simple applications as the one depicted in Illustration 44. A MicrOringTM seal is any o-ring that measures less than 1 mm in either inside diameter ID or cross section CS. Static Crush Seal Gland Dimensions.

Speak with an engineer today at 603-468-3600. With millions of products produced and shipped annually we are the experts your organization needs to seal the success of your application. Free shipping on qualified orders.

In crush seal applications the O-ring is completely confined and pressure deformed crushed within a triangular gland made by machining a 45 angle on the male cover. The largest selection of microminiature o-rings anywhere. Temperature Range Description N70 Nitrile 70 5.

O-Ring Installation Design and Specification For Dynamic Applications. There is no loosening of pressure over time as there will be with clamped parts used on face seals. MS 28783 back-up rings match the dash numbers an AN 6230 O-rings.

Engineering support services are available for a fee for expert help optimizing critical applications. Flange seal Radial seal Dovetail seal Boss seal. Microminiature composite seals and custom-engineered microminiature.

The OD of the ring should be about the same as the recess diameter. Review the general o-ring groove design considerations before moving onto the specific o-ring gland design type. Commonly called a crush seal design triangular groove designs have established a proven track record of success in numerous industries.

This use of an O-ring is a variation of the static seal. The od of the ring should be about the same as the recess diameter. Good practice is to use a back-up ring on either side of the O-ring even though the pressure on the ring may be from one side only.

O Ring Groove Design Global O Ring And Seal

Seal Thinking Seal Design Guide Apple Rubber Products

O Ring Groove Design Global O Ring And Seal

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

Triangular O Ring Grooves Mechanical Seal Engineering Eng Tips

0 comments

Post a Comment